- Home

- About

-

Our Products

ELECTRIC HEATERS & HEATING ELEMENTS

- Tubular Heaters|Air Heaters

- Process Immersion Heaters|Tank Heaters

- Band Heaters

- Heat Tracers | Cable Heaters

- Silicon Rubber Heaters

- Heated Hose / Hose Pipe Heaters

- Etched Foil Heaters

View All

TEMPERATURE SENSORS & ACCESSORIES

- Thermocouples

- RTD Sensors

- Thermocouples Wires & Cables Accessories

- Temperature Transmitters

View All

- Technical

- Testimonial

- Contact us

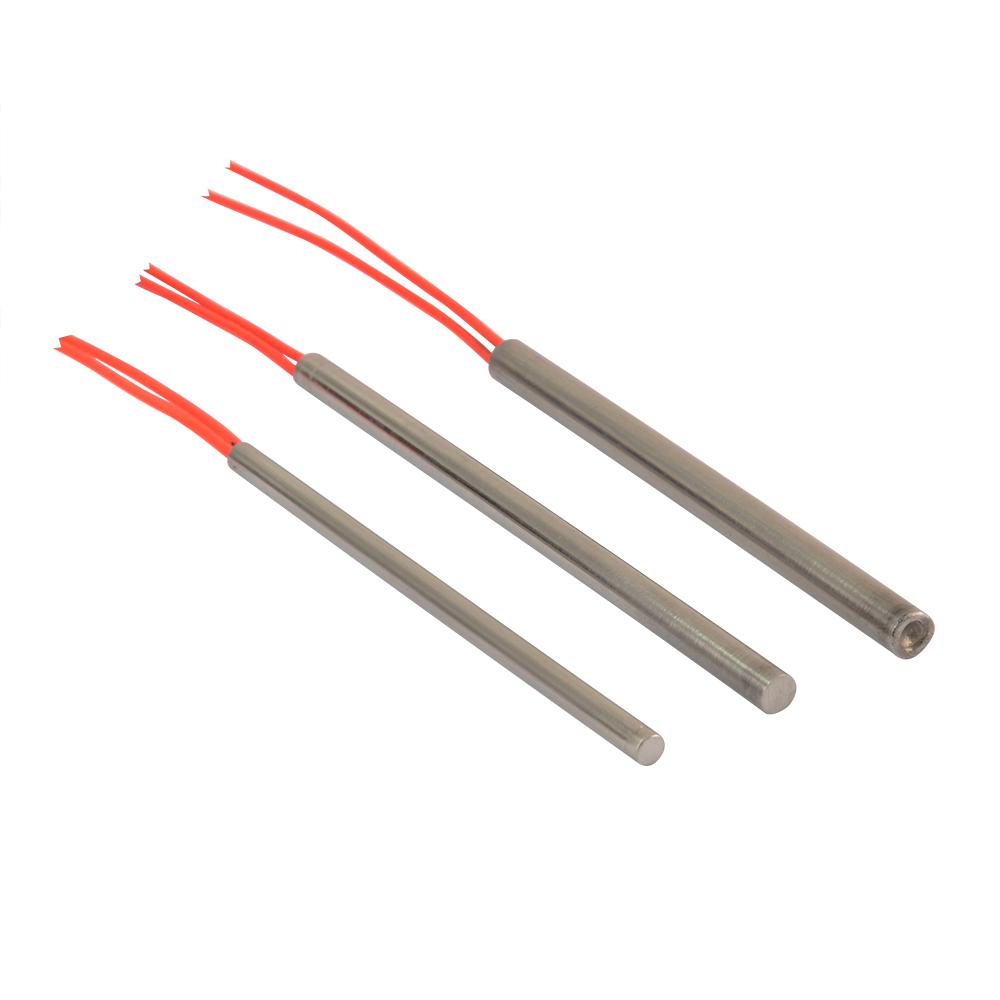

HI-Density Miniature Cartridge Heaters

The small sizes of these heaters provide lower internal temperatures and faster heating response times. Swaged construction allows for higher watt densities, higher operating temperatures, and longer heater life. They come in three sizes:

- 1/8" diameter

- 5/32" diameter

- 3/16" diameter

The standard sheath material is 304 Stainless Steel which provides good thermal conductivity and resistance to corrosion and scaling. The welded end disc made from the same material as the sheath provides a positive seal against moisture and other contaminants. Grade “A” Nickel-Chrome resistance wire precisely wound on a high purity magnesium oxide core places the resistance wire as close to the inside of the sheath as possible. A high purity Magnesium Oxide (MgO) powder is used to fill all remaining space inside the sheath. Heater is then swaged, which compacts the magnesium oxide grains into a solid mass.

The standard termination is a Teflon® plug with Teflon® leads (Type M3) with internally connected leads that provide flexibility and allow the leads to bend sharply as they exit the heater.