- Home

- About

-

Our Products

ELECTRIC HEATERS & HEATING ELEMENTS

- Tubular Heaters|Air Heaters

- Process Immersion Heaters|Tank Heaters

- Band Heaters

- Heat Tracers | Cable Heaters

- Silicon Rubber Heaters

- Heated Hose / Hose Pipe Heaters

- Etched Foil Heaters

View All

TEMPERATURE SENSORS & ACCESSORIES

- Thermocouples

- RTD Sensors

- Thermocouples Wires & Cables Accessories

- Temperature Transmitters

View All

- Technical

- Testimonial

- Contact us

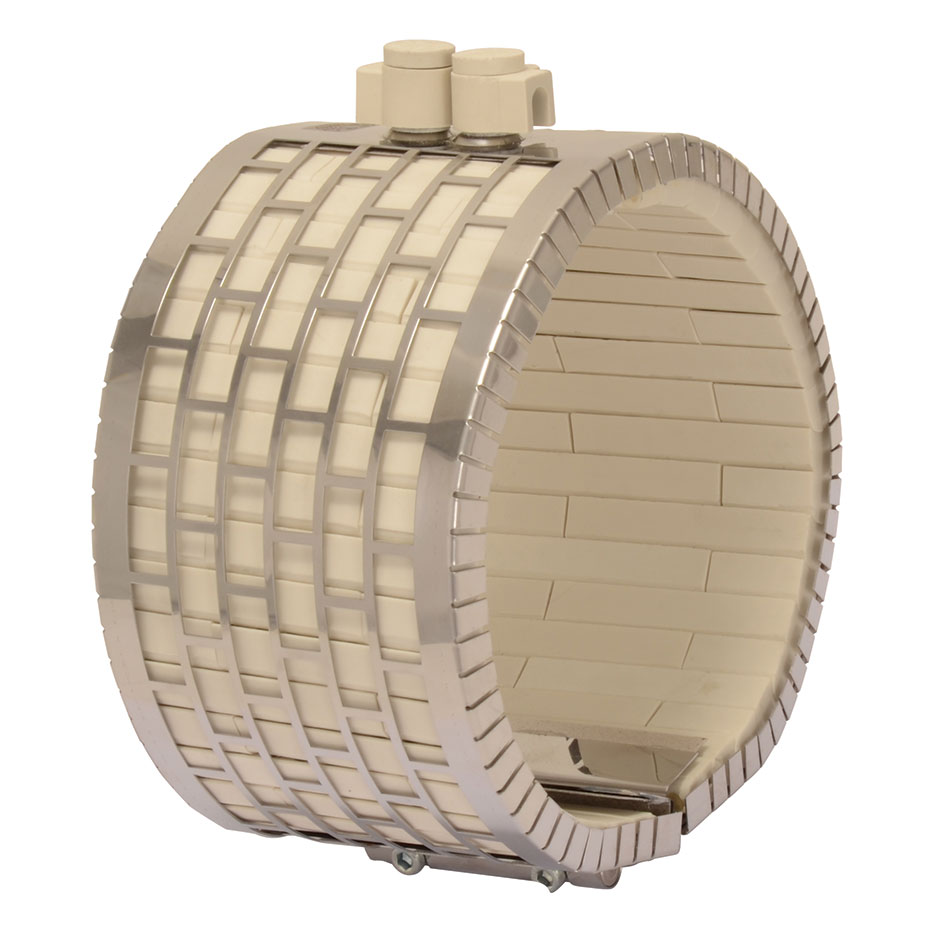

Ceramic Band Heaters

A helically wound resistance coil made from nickel-chrome wire is precisely strung through specially designed ceramic insulating bricks, forming a flexible heating mat. TEMPCO's style of Ceramic Insulating Bricks offers several benefits including:

These heaters transmit heat through both conduction & radiation. The element winding is designed to heat the ceramic blocks to the point at which they radiate energy into the barrel as well as conduct energy by being in contact with the barrel - fit is not as critical as in other types of bands